Available Materials for CNC Machining

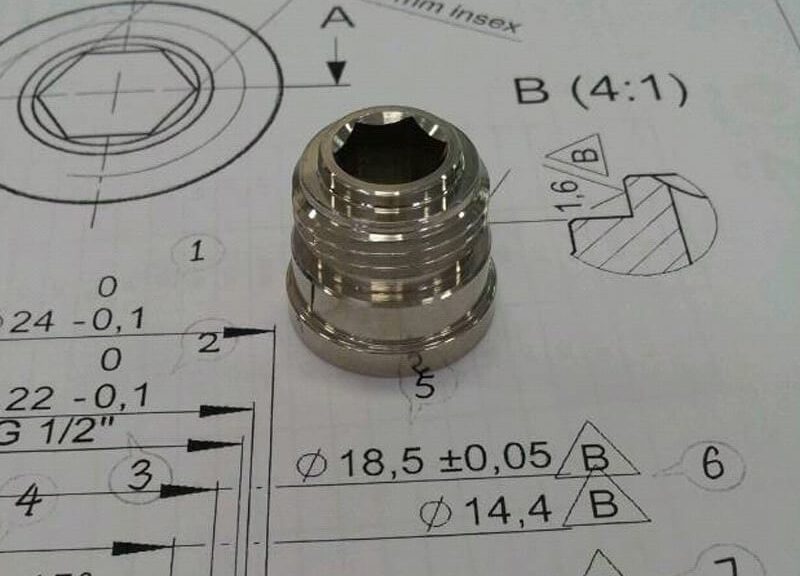

| Available Materials for CNC Machining/turning/milling | Aluminum: AL2024-T3/AL5052/Al6061 / Al6063 / Al6082 / Al7075 / A380, etc. Steel: Alloy Steel 4130/Alloy Steel 4140 /Steel 1018/SS 303/SS 304/SS 316,316L/SS 420, etc. Plastic: ABS / Acetal [Delrin] / Acrylic / Nylon PA66/6 / PEEK / PTFE [Teflon] / POM / PMMA / PP / PC, etc. Cooper: C11000 / C12000 / C12000 / C36000, etc. Brass: Brass C36000 / C37800 / C35000 / C34500 / C28000 / C27400 / , etc. Titanium: TA0 / Grade 1 / Grade 2 / Grade 4 / TB5, etc. Titanium Alloy: Ti6AL4V-Grade/ Ti-17,etc |

| Surface treatment | Surface treatment: Brush, Polishing, Electroplating, Galvanizing, Black bright anodized,Powder Coating,etc. |

| Precessing way | CNC Milling, CNC turning, Grinding, Wire cutting, EDM,Drilling, etc. |

| Manufacturing Equipment | 3-,4-&5- axis Machining Center , CNC Lathes and Turning Machines, CNC Milling Machines,CNC Grinders, CNC Laser Machines,CNC Electrical Discharge Machines (EDM), CNC Plasma Cutting Machines, |

| Inspection Equipment | Vernier Caliper, Micrometer Caliper,Go/No-Go Gage,Thread Gages,2D Projector,3D Measure Instrument, CMM, Spectrum Analyzers, Microscope, Altimeter , Hardness Tester,Roughness Tester, Profilometer ,Ultrasonic Cleaning Equipment,etc. |

| Tolerance | ±0.05mm |

| Drawing Format | PDF/DWG/DXF/IGS/STEP,etc |

| Quality Management System | ISO 9001:2015 |

| Packaging | PE bags with sponge, recycle plastic box,wooden crates or boxes or based on customer’s requirement |

| CNC machining parts used for many fields: | Medical Industry,Aerospace Industry,Transportation Industry,Military and Defense Industry,Electronics Industry,Marine Industry, etc |

Production Capacity

☼ Manufacturing Equipment

▷ 3-,4-&5- axis Machining Center

▷ CNC Lathes and Turning Machines

▷ CNC Milling Machines

▷ CNC Grinders

▷ CNC Laser Machines

▷ CNC Electrical Discharge Machines (EDM)

▷ CNC Plasma Cutting Machines

☼ Surface treatment

▷ Brush

▷ Polishing

▷ Electroplating

▷ Galvanizing

▷ Black bright anodized

▷ Powder Coating, etc.

☼ Inspection Equipment

▷ Vernier Caliper

▷ Micrometer Caliper

▷ Go/No-Go Gauge

▷ Thread Gages

▷ 2D Projector

▷ 3D Measure Instrument

▷ CMM, Spectrum Analyzers

▷ Microscope

▷ Altimeter

▷ Hardness Tester

▷ Roughness Tester

▷ Profilometer

▷ Ultrasonic Cleaning Equipment, etc.

FAQ

❃ What’s your main service?

√ We’re specialized in custom quality CNC machined parts.

❃ Do you have rich experience?

√ We have over 20 years of experience in the CNC machining industry and our Sales are good at English communication.

❃ How do you ensure every process’s quality?

√ 1. Raw Material Inspection

After the raw materials are purchased, the quality department checks the dimensions, hardness, and composition.

√ 2. In-Process Quality

During the production stage, our workers will inspect the product dimensions to ensure that everything passes.

√ 3. QC Inspection In

When the machine is producing parts, our QC staff will inspect it from time to time to ensure the quality.

√ 4. Full Inspection

Batch production is completed and a full inspection is performed. Check if each dimension is qualified.

√ 5. Surface Finishing Inspection

After the product is surface treated, QC needs to check if the surface meets the quality requirements.

√ 6. Inspection Before Packaging

A final surface inspection is done on each product before packaging and shipping

❃ Where is your factory located?

√ We’re located at Jiangshan Industry Park,Yinzhou District,Ningbo,China

❃ Which port do you use for shipment?

√ Ningbo Port

❃ How long does it take to get a quote?

√ The quotation will be provided within 1-2 days after receiving RFQ with clear information

❃ How long is the lead time for ordering?

√ The production lead days are usually within 20-40 days based on quantity.

❃ What are your payment methods and terms?

√ 30% T/T in advance and balance 70% paid after bulk order completed.

❃ Can I send your our parts’ design?

√ Yes, drawing format can be PDF/AutoCAD, SolidWorks, and Pro/E software

❃ Can you do assembly?

√ Yes, We have 8 assembly lines.

Our factory

Packaging & Shipping

PE bags with sponge, Recycle plastic box, Wooden crates or boxes or based on customer’s requirement

We have grown very rapidly in recent years due to our low cost, on-time delivery, and defect-free quality. We strive to help customers achieve their goals by communicating with them at all stages of component manufacturing. and send us drawings (AutoCAD, UG, Pro/Engineer, Solidworks) for a free quote for your next project, we will be the following up within 24 hours!